We often hear the opinion that in Ukraine, old houses, old businesses, and old fortunes rarely survive. We live in an environment that is too turbulent, where too much changes every day. That is why stories of family businesses that have stood the test of time are so interesting and heartwarming.

Since 1998, "Velma" has been operating in Kyiv—a sewing workshop that fulfills orders for Ukrainian brands, designers, and stores. Children born in 1998 are now fully grown adults. Many projects that started back then have long since ended their life cycle or did not survive the multiple crises we have faced. But not "Velma."

— If you do something, do it well — this is the core principle of "Velma," a business known throughout Ukraine and beyond.

The business is run by the whole family—parents Natalia and Mikhail, along with their son Andriy. They recently appeared on television after Andriy Akopov, a military serviceman and entrepreneur, received a grant for veterans to develop his business. But the workshop was established when he was just ten years old. How to stay afloat through all the political and economic upheavals, crises, and war while remaining true to oneself—this is the story we are about to tell.

"Velma": The Beginning

The business started with used sewing machines and a small-scale production of children's clothing. At that time, there wasn't enough of it to meet the demand of all buyers, making it highly sought after. Natalia Akopova took charge of organizing the workshop's operations, where her experience as a sewing production technologist proved invaluable, while Mikhail Akopov handled the business side—management, procurement, and finding partners.

— This is my profession, and it's what I love, so starting out wasn’t difficult, recalls Natalia. I was supported by Mykhailo Andreevych. He took on all the managerial responsibilities and faced all the challenges. I mainly focused on selecting additional materials, models, and accessories. They had to be sourced from somewhere, had to look good, and had to stand out from the rest. I spent most of my time on that.

When it all was just beginning – the Velma band relaxing in nature, 2001.

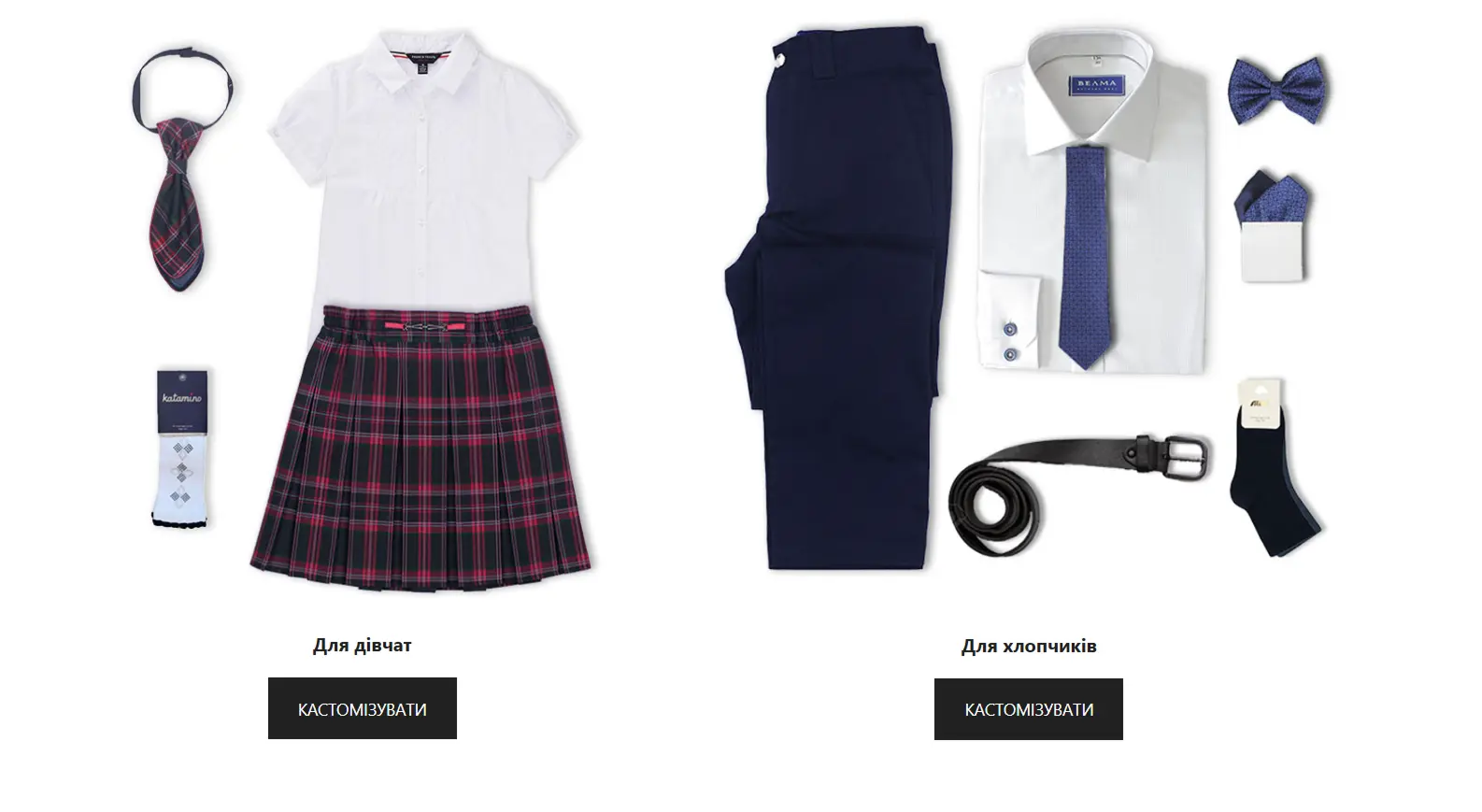

Back in the late 1990s, when "Velma" began operations, school uniforms were in high demand. They were ordered in bulk, purchased collectively... There were heated debates about which ones were the best! As a result, the workshop quickly adapted to meet this need.

They sewed, negotiated with small shops and retail outlets, signed contracts with vendors, and offered their products to schools. Natalia often visited children's stores, especially when traveling abroad, looking for interesting designs, accessories, and models.

Back then, photos weren’t taken, so designs had to be sketched or memorized and later adapted for school uniforms.

— When little ones start first grade, says Natalia, — it's important that they can dress themselves. A six-year-old boy or a little girl going to first grade should be able to change for gym class on their own. It’s not kindergarten anymore—they need to put on a blouse, a pinafore, and undress by themselves. Children should feel comfortable running around at school. We looked for comfortable cuts, natural fabrics that could withstand multiple washes without losing shape. If I saw a skirt I liked, I would take inspiration from the model, adapt certain elements, and bring it to production. As a technologist, I was particularly interested in how to process details properly, so the clothing was both quick to sew and comfortable to wear. One of the most time-consuming aspects was the accessories. They increase sales by fifty percent. For example, we had a blouse with a blue trim. To complete the look, we needed white-and-blue buttons to match. The same went for burgundy trim—we specially ordered the production of these buttons from another country.

Andriy Akopov remembers:

— I was ten years old when the business started. I never thought about being involved in the company’s work—I just always helped out with whatever was needed, like unloading boxes or bringing water. Water was essential in the workshop for the ironing systems, but we didn’t have water filters back then, so we had to bring it from purification centers. My father and I would go every week, fill up water containers, and carry them up to the third floor.

The company faced an immediate and difficult decision: should they focus on producing "a lot and cheap," or should they invest in higher-quality, more expensive materials, put more effort into production, and purchase premium fabrics? Each option had its own target audience and marketing strategy. In the end, they chose the second path, even though the first would have been easier and more competitive. They have remained true to this approach to this day.

They sourced fabric from the Chernihiv factory—high-end and exceptionally durable material. We're talking about the late ‘90s and early 2000s, about old Soviet-era factories—but there was nothing quite like what Chernihiv was producing, even in neighboring countries. The school uniforms had to withstand the wear and tear of active children, be comfortable but not too baggy, and last through at least two years of heavy use. They had to figure everything out from scratch.

Participation in the exhibition, 2006

At the time, entering retail chains was somewhat easier. Even though the clothing was priced above average due to the high-quality materials and Kyiv-based production, interest in it gradually grew among various retailers. The uniforms were sold both in Kyiv and beyond. Growth may have been slower than that of cheaper brands, but it was steady.

Working with major retail chains required large, simultaneous batch deliveries. It wasn’t enough to supply small amounts and restock weekly. This meant the company had to gradually expand.

The company regularly participated in trade exhibitions—these were dynamic events where they had to learn from competitors.

Opening of the "School Country" store, 2014

To appeal to parents, they used marketing strategies that today’s experts would recommend.

For example, under their brand, they offered additional products to stores by partnering with manufacturers and even producing accessories themselves—ties and belts for boys, hair clips and knee-high socks for girls, shoes, and socks.

They also organized fittings right at the factory. There wasn’t a dedicated showroom, but they had a full range of products. Small shops usually placed simplified and limited orders, but the selection at the workshop was broader and more interesting. At the time, it was common practice to buy directly from manufacturers—it seemed cheaper than purchasing from stores with retail markups.

Babyexpo exhibition, 2018

Family fittings before the start of the school year were a major event, especially when a child was entering first grade. Parents would bring not only their children but also grandparents, aunts, and uncles. The little star of all the commotion could easily become tired and overwhelmed, so to cheer them up, they would receive a small gift at the end.

Eventually, people started coming for uniforms not just from different cities in Ukraine but also from neighboring countries.

Natalia Akopova remembers:

— When they showed the first day of school on TV, from different schools in different cities… or when I walked around the city on September 1st, I could see how many children were wearing our uniforms. That made us so happy.

However, over time, school uniforms gradually stopped being a mandatory part of children’s wardrobes, and retail demand for them declined as well. It was time to decide what to do next.

Overcoming the First Crisis

The decline in demand for school uniforms hit Velma at the peak of its production cycle. Fabrics, threads, and other materials had already been purchased in advance, annual plans were in place, and suddenly, there was significantly less work. In such situations, everything starts to collapse—experienced staff leave, income drops, and covering expenses becomes increasingly difficult.

At that time, Andriy Akopov, the owners' son and a business partner, was working in advertising. He hadn’t planned to join the family business beyond occasional help, such as designing a website or making signage.

But when the crisis hit, the family came together, and Andriy became deeply involved in the company. He took charge of business promotion—SEO, networking, and advertising, including paid ads. He even went directly to schools, offering school uniforms, though their demand was fading. He spent most of his time at the workshop, communicating with employees, diving into the production process, and managing everything related to marketing.

Running active social media and properly filling the website required being constantly present at production while simultaneously thinking about how to translate all this information into keywords and content. He also had to find ways to communicate key messages effectively during negotiations with potential clients. Essentially, advertising meant being the bridge between consumers and the business, bringing them closer together.

A manufacturing facility that pays rent, maintains equipment, and covers wages cannot afford to be idle. To avoid losses, it must continuously produce and sell, minimizing excess inventory.

By chance, Andriy learned about the “Всі.Свої” (Vsi.Svoi) market and attended one of its events. It wasn’t the first of its kind, but it was crowded and popular, making it clear that Velma needed to participate. At the next market, they were already exhibitors, and they continued to participate two more times.

2018, "All Ours"

Gradually, the search for a new niche led to a model where material purchases were no longer a financial risk. This approach involved the client providing the materials while the workshop first produced a sample and then manufactured only as many items as needed.

Their vast experience in production became a solid foundation for offering tailoring services. They primarily took on orders similar to their previous school uniform line—suits, coats, blouses, and more.

To adapt, the production process had to be restructured, including hiring pattern makers to develop new designs. However, the client-supplied material model had its limitations—established players in this field often provided their own fabrics.

— We gradually found our place among custom clothing manufacturers, — Andriy recalls. — Producing clothing piece by piece was unprofitable for us, which further narrowed our focus to B2B clients. Brand owners, showrooms, and clothing stores placed orders with us for specific models that they then sold independently. Occasionally, we fulfilled corporate orders as well.

Their experience in factory-level school uniform production left them with specialized equipment that enabled the efficient manufacturing of high-quality adult clothing. Pocket-setting machines, buttonhole and button-sewing machines, pressing and cutting equipment—small workshops rarely had such tools. This provided Velma with a competitive advantage and defined their specialization. They found their niche in women's business attire—suits, blazers, trousers, skirts, and, especially, women’s shirts and blouses.

The transition was extremely challenging—relocating to a new facility, hiring new staff, and dealing with small orders and meager salaries. Fortunately, the seamstresses remained loyal to the company. They felt comfortable working there, and they were Velma’s people.

War

— On February 24, we didn’t go to work. The seamstresses decided to leave, and we also temporarily left Kyiv. Everything in the workshop remained just as it was the day before, — Andriy recalls.

For a time, work came to a complete halt, and restarting it remotely was impossible.

Later, Andriy Akopov joined Ukraine’s defense forces, while his parents remained in evacuation. Many Ukrainians know firsthand what "evacuation" truly means.

However, an abandoned but not officially closed production facility presented its own challenges—at the very least, utility bills for the idle workshop still had to be paid. Gradually, the family decided that Andriy's parents would return to Kyiv and slowly resume work. Meanwhile, Andriy, still serving in the military, began assisting with advertising remotely.

When the seamstresses left the country at the start of the full-scale invasion, almost all of them quickly found new jobs. This meant that restarting production required assembling an entirely new team—at a time when skilled labor was scarce. In essence, the workshop had to be rebuilt from the ground up.

New Team "Velma", 2023

The company’s founder, Mykhailo Akopov, believes that the psychological mindset of employees plays a crucial role in ensuring quality. This meant that working with new hires had to begin with instilling the right approach to organizing production.

Thus, the Velma family found itself among thousands of Ukrainians who worked to rebuild life in the country—despite shelling, power outages, and uncertainty.

Natalia Akopova says:

— The materials market has changed for the worse. Good buttons and quality fittings are nearly impossible to find. War shut down the factories that produced them. Even the textile mills that once made fabric for school uniforms no longer exist. Nobody produces high-quality wool-blend fabric anymore.

Everyone feels the lack of time, electricity, and certainty about the future. But adapting to the new reality is possible.

With a shortage of skilled workers, the company must invest in more productive, modern equipment to keep growing—but that requires funding. Every day is a whirlwind of events, making long-term planning essential, yet nearly impossible. Grants provide some support—one such initiative has even featured Velma as a veteran-led business in need of assistance.

Andriy Akopov is determined to continue securing grants, focusing on veteran and displaced-person employment, as well as adopting new technologies to strengthen Velma’s position. This year, the business received financial and expert support within the framework of the veteran business development program "LIVING TOGETHER." This program was initiated and implemented with funding from FUIB, implemented in partnership with the Future Development Agency and the KSE Foundation.

The company started with small orders, working with individuals launching their own clothing lines, as well as domestic and international brands in need of production for their collections.

Surprisingly, Velma still receives inquiries from parents who once wore the company’s school uniforms and now want the same quality for their children’s first day of school. This means Velma is now clothing a second generation of Ukrainian students.

Looking ahead, the family plans to share their expertise by training future seamstresses.

— I would love to teach, — Nataliya says. — If there were people willing to learn, we’d employ them, too—we need skilled professionals, and there just aren’t enough of them in Ukraine.

Building an Online Presence

Andriy Akopov shared insights into the evolution of Velma’s website from the company's early days to the present.

— My marketing journey began even before I officially joined the company.

The Velma website was created back in 2002 by a programmer chosen by my father. I remember trying to make my own proposal by involving a classmate in the development. However, despite the challenging three-way communication, the project never took off. My father chose a different developer.

In 2011, I worked closely with photographers on a project for creating graduation albums. Although I didn’t know programming, I understood what I needed, and they recommended a website builder, which is still the platform used for Velma’s website.

The design and content of the site are a story of their own. Using the new builder, I was able to create a modern online store for school uniforms. Besides my visits to schools in Kyiv, I also tried promoting the uniforms online wherever I could: in Google search, on Google Merchant Center, Facebook Marketplace, Etsy, and Amazon (I even managed to list a few products on Amazon, but the effort later required significant resources). I categorically refused to use Rozetka and other marketplaces, believing that our product should be sold directly from the manufacturer on the domestic market.

Intensive promotion was underway: reviews were collected on Google Maps, first publications were created on social media, ad campaigns were launched in Google Ads and Facebook. Google Analytics was monitored, and search engine optimization was carried out. A lot of work was done in Google Sheets to create and adjust feeds for our accounting system, website, and Google Merchant Center.

When the shop switched to custom sewing, I returned to work on the website. A significant amount of work was done to transform the website from a school uniform store to a sewing shop site, including SEO, creating ad campaigns in Google Ads, and gathering reviews on Google Maps for the sewing shop. To keep the website’s good position, this work must continue, though with less intensity.

Andrey Akopov at production

Andrey Akopov at production

At the same time, I created social media pages for the shop (I didn’t want to replace the pages dedicated to school uniforms with sewing shop pages because we hadn’t abandoned that brand). School uniforms remained, but took a backseat. I actively filled Instagram and simultaneously learned to find angles, write texts, and post content. We were building a new target audience.

The questions of how to increase orders, strengthen the website’s position, and expand the target audience constantly worried me. In 2021, I got the idea to place a "product configurator" on the website, which could bring us closer to the retail consumer. I saw a version of such a configurator for women’s shirts, which allowed consumers to choose the model of the shirt by selecting the fabric, collar style, cuffs, fasteners, and other details. Searching for a ready-made product that could implement this led me to solutions that could be placed on popular CMS platforms like WordPress, Shopify, Magento, etc. I got excited about the idea. But the implementation was quite complex.

As a result, the need arose to purchase hosting and create an additional website on the WordPress platform. After analyzing service providers, I chose Cityhost.

The configurator for blouses still hasn't come to fruition, but a unique customizer for school uniforms is working, with no analogs.

Now I have shifted the company’s promotion focus from online to offline: I participate in grant programs, attend events dedicated to veteran businesses, network, meet colleagues, look for partners, and appear in the media.

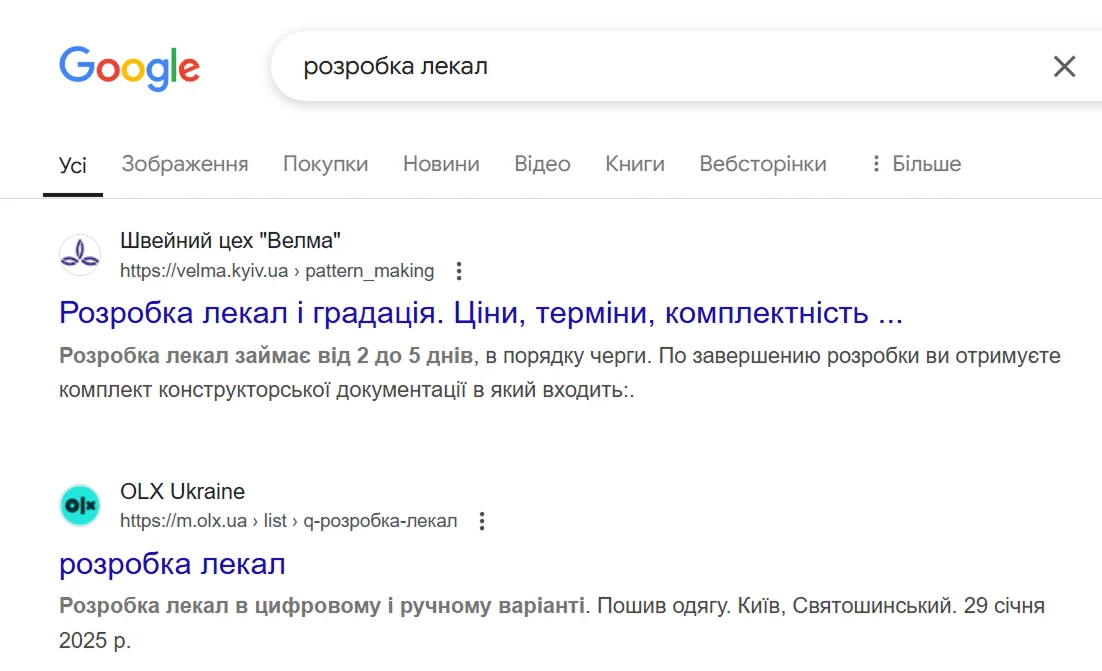

Even now, while serving in the military and unable to dedicate as much time to the business, his work on the website continues to deliver results. For example, Velma’s site ranks first on Google for search queries like “pattern development”:

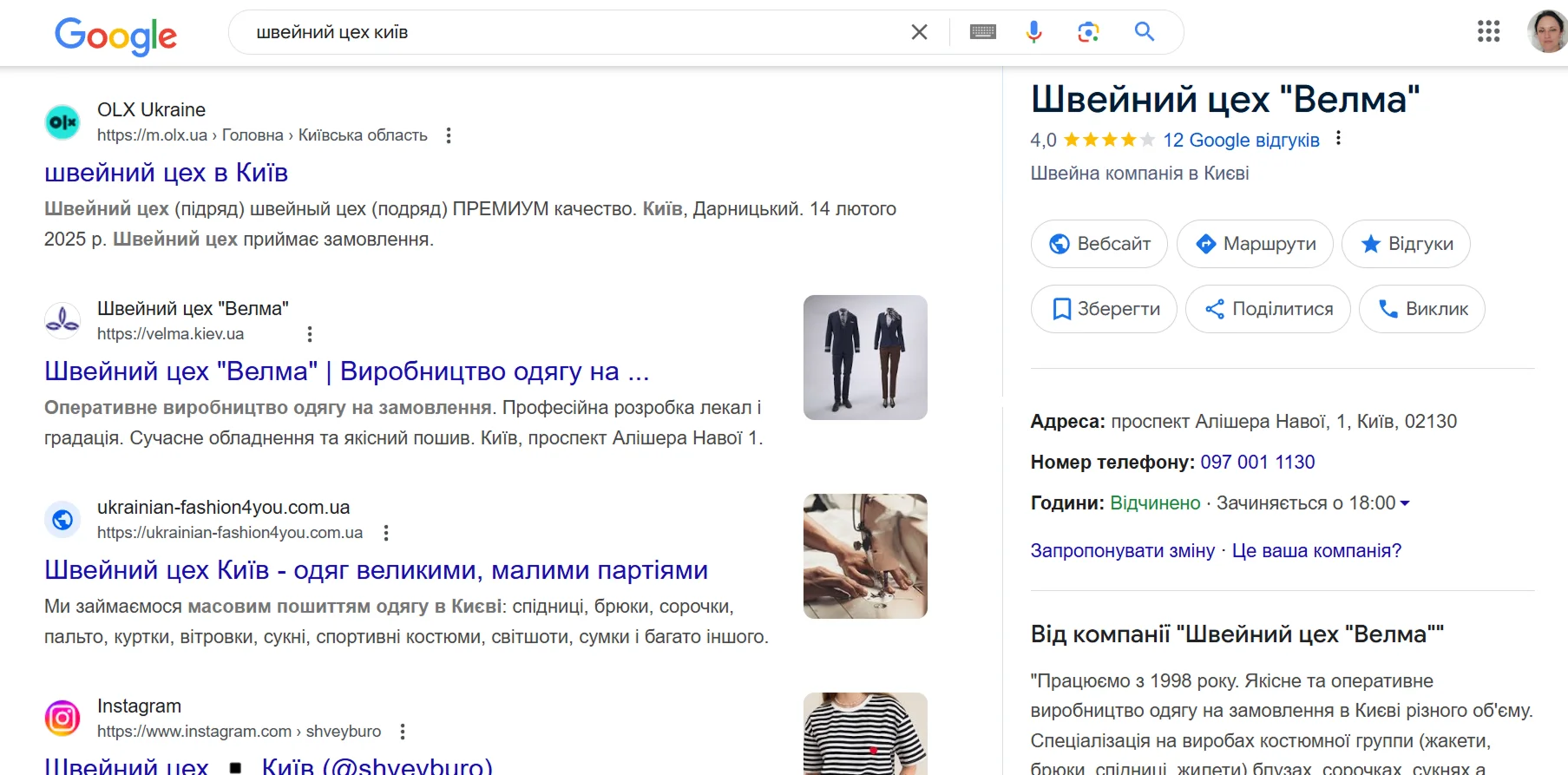

And “sewing workshop Kyiv.”:

Anyone familiar with SEO for competitive keywords knows that such rankings require consistent effort—content optimization, link-building, collaborations with industry platforms, and active social media presence.

— I have a feeling that soon the market will be oversaturated with clothing, making sales even more challenging, — Andriy notes. — This is already difficult due to the abundance of cheap Chinese apparel flooding the market. My long-term goal is to maintain our niche and establish a recognizable clothing brand. That would provide stability and independence. However, transitioning from a service-based business to direct sales is complex, as the market is already crowded. At the same time, Velma remains committed to school uniforms, aiming to sell them both domestically and internationally. Another promising segment is men’s shirts and polo shirts. It’s also crucial for us to avoid conflicts of interest with clients who currently outsource their clothing production to us. Maintaining our niche would help us steer clear of such issues. That’s the next step we need to take.