The "Military Brotherhood" Charity Fund consists of ordinary guys and girls from Zaporizhzhia who manage to find time between work, studies, family matters, and enemy shelling to meet the needs of the front lines. They work with passion, as the majority of what they create consists of explosive surprises for the enemy: mines, mining systems, drop systems, and smoke munitions.

In addition, the volunteers service drones, which involves repair, upgrades, calibration, development of drop systems, firmware for controllers, remotes, and UAV transmitters/receivers.

Currently, a small team of 20 volunteers collaborates with over 40 units of the Armed Forces of Ukraine, including Special Operations Forces, the National Guard, Territorial Defense brigades, and others. They supply an entire arsenal of munitions, devices, and various components needed at the front lines across all directions — from Kherson to Kursk.

The volunteers include people from various backgrounds, aged 17 to 75: students from electrical engineering colleges, dental technicians, active military personnel, internally displaced persons, sappers, specialists from different production fields, accountants, economists, and technologists. Some specialists even assist remotely from different parts of the world.

They are engaged in the comprehensive development and production of combat systems for mission fulfillment. This involves complete workflows, starting from the idea and concept to the finished product delivered to the front lines.

One of the key projects involving the "Military Brotherhood" volunteers is "Nemo". This group, which includes military personnel, produces a significant volume of munitions for drones. Various "incendiary and smoke candies", UAV drop systems of different types and weights — Mavics, FPV-7 and FPV-10, Vampires, and more — are among the most requested gifts for the occupiers by units stationed in Ukraine's hot spots.

Another important area of work is 3D production and munitions created with its help: anti-personnel mines, remote mining systems, tail sections, and parts for various types of aircraft. These include thousands of components printed on 3D printers, which are used in large quantities and are essential for the daily operations of our military.

The fund has been in existence for less than a year, but thanks to their support and the "Nemo" project, fighters on the front lines have received over 16 tons of munitions of various types for different combat purposes.

Facebook Report: Sappers from the "Kara-Daga" unit demonstrate how PMN-2 anti-personnel mines, printed on a 3D printer, work — see the link for details.

But that's not all! Another project involving the fund's volunteers is the Antimine Boots, a leg protection system against anti-personnel mines created in collaboration with EM Secure Systems. It is designed for humanitarian demining and to protect specialists conducting these operations.

The story behind the creation of this project is very intriguing. Anatolii Honcharenko, one of the founders of the fund, lived in Cambodia for many years but returned to Ukraine when the full-scale invasion began to be at home during these challenging times for the country.

— The idea for creating anti-mine boots came directly from my knowledge of Cambodia's history, — says Anatolii. — Even now, 1000 square kilometers of territory there remain mined. Thirty years have passed since the war, but its legacy still claims civilian lives. Every year, 500 to 1500 people fall victim to mines. I want to ensure that such a fate never befalls my country…

We will share more about this innovation later, but for now, let’s ask Anatolii Honcharenko about the history of the fund's creation, the people who work there, what inspires them, and the challenges the volunteers face.

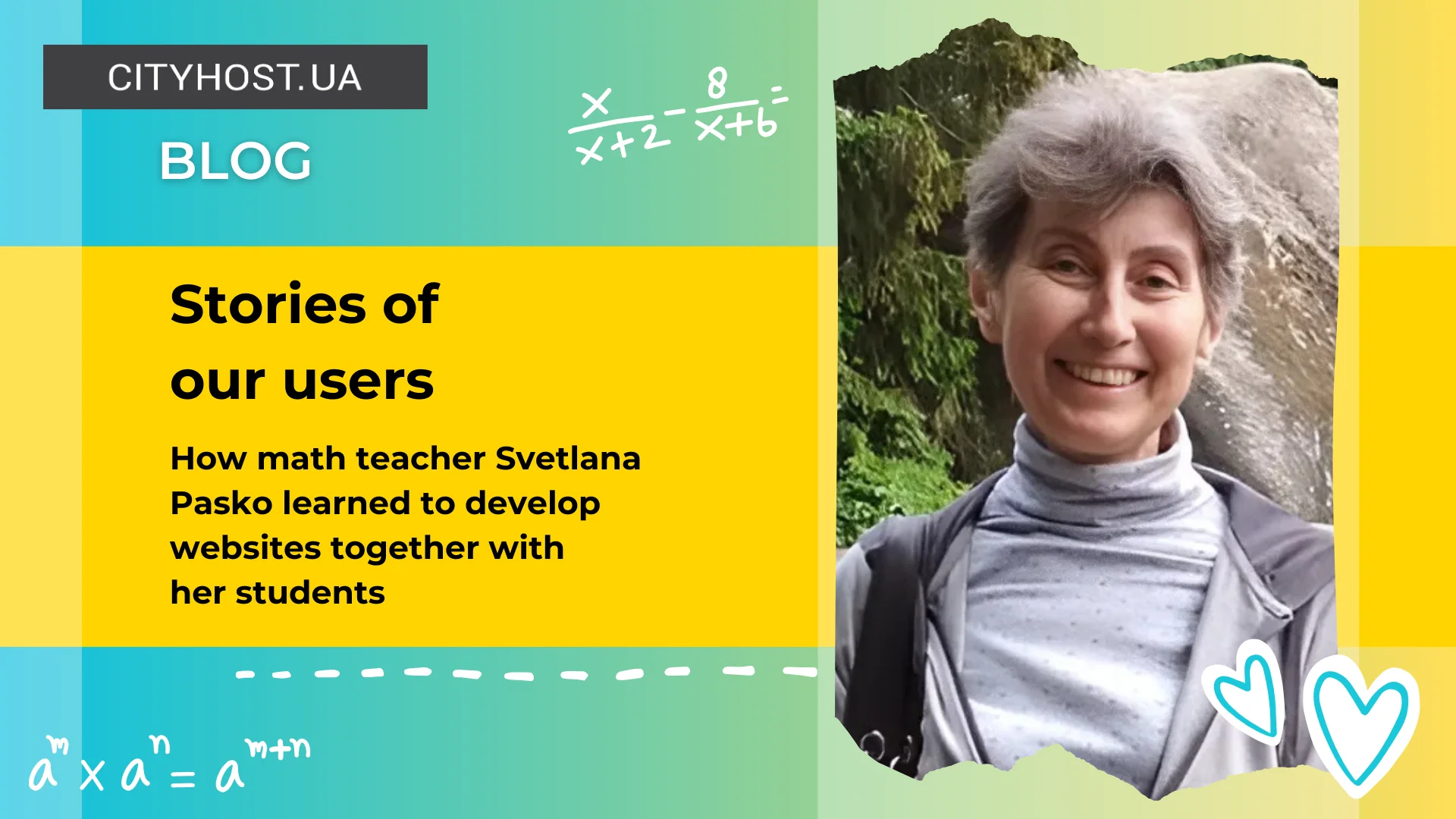

— Our work began in February 2024. There were just three of us: Mykhailo Savenko, Yurii Pereslavskyi, and me. Occasionally, a few more volunteers joined us when they had free time. But we lacked enough hands, and there was at least enough work for a large team, not to mention issues with space. Still, we made do with what we had, and nothing could stop us. Those were good times!

Throughout the city, there were several small rooms and spaces where printers were set up, storage facilities where we soldered electric matches and batteries for incendiary and smoke munitions, and disassembling e-cigarettes donated by volunteers.

We often ran out of space to set up equipment and workstations. We had to work on the floor in dirty spaces and boarded-up warehouses. Sometimes the available space was just one square meter, while the rest was filled with parts, components, and boxes. Some equipment and printers were housed in Mykhailo’s dental lab, where assembly and 3D printing operations also took place.

At night, Mykhailo, working as a dental technician, completed his orders, and during the day, he was immersed in volunteer activities. Sometimes it seemed like he only slept two or three hours a day, constantly staying busy. Yurii, a student at an electrical engineering college, balanced his studies with volunteering. He managed to attend classes, help his parents at home, and spend the rest of his days and nights with us, handling much of the ongoing work.

Everyone stayed late, working to the limit. Nobody had a fixed schedule. There was an overwhelming amount of work, and everyone understood that stopping wasn’t an option. We all found joy in what we were doing, and we were happy to help our guys on the front lines. Requests kept increasing — many of them were directly related to munitions for drones and 3D-printed components for pilots and infantry. This motivated us to take the next steps.

Money was extremely tight — just what we earned ourselves and contributed to the cause. There were no donations, and we needed help and financial support as the workload increased and demands grew. That’s when we decided to establish a charity fund. We debated the name for a long time, searching for the right combination, and finally decided on "Military Brotherhood". This name united us all under the slogan, “Everyone on their own front!”.

Our fund hasn’t even been around for a year yet, but many people have already contributed to its development, helping with production, while some have gone on to fulfill their duty to the country. Recently, two of our volunteers were drafted and have joined the ranks of the Ukrainian Armed Forces.

Given the shortage of specialists, it’s incredibly challenging to find people who can assist us now. I’ve started to view the people around me differently, appreciating and cherishing them deeply. The fund has become a second family for all of us.

These individuals, despite the hardships in their lives and the country, do their work every day. Day in and day out, from morning till night, they dedicate their time for our shared Victory. They are like vital organs in a large organism, working seamlessly together without a hitch, always reliable.

If I am the head of the fund, then Yurii and Mykhailo are the heart and soul of the "Military Brotherhood". The men and women who work on the fund’s development, manage media resources, and handle daily routines and production processes are our backbone, our support. Each of us has made a significant contribution to the fund’s growth, with our own roles, responsibilities, and tasks.

The main activity that has always supported me is the company "Optima-plast", where I am a co-owner. We manufacture medical products. My partner and employees volunteered at the beginning of the full-scale offensive and are now serving in the army. Only women and older people remained at the enterprise, and they continue to carry all production on their shoulders. Despite these difficulties, we continue to help not only the charitable foundation "Warrior Brotherhood", but also the foundation "Soldier's Rest", which has been operating since 2015.

— Can you tell us about some of your interesting developments that are already in use?

— We have developed, successfully tested, and started supplying the front lines with several models of remote mining systems. We even have a museum exhibit where we’ve collected a small portion of the components we’ve worked on.

By working directly with drone pilots and sappers, we’ve introduced upgrades to many models for various purposes, such as remote-deployed mines, ground-controlled PMN-2 mines, and more. The full range of our 3D-printed products is showcased on our media platforms — Facebook page, Instagram, TikTok, and Telegram channel.

Military personnel constantly send us video reports showing how our drop systems and incendiary smoke munitions from the "Nemo" project perform. These reports highlight how entire minefields are cleared, enemy warehouses are destroyed, roads are mined, and much more. It’s gratifying to know that we are helping our country and saving lives.

— What types of requests do you most frequently receive from the military?

— The requests vary constantly. However, the volume is consistently growing, and more military units are reaching out to us. There are many orders for 3D-printed products, ranging from remote mining systems to anti-personnel mines, tail sections of various types for mines and munitions, which units assemble themselves in their labs, and specific components for drones and aircraft. Every day brings something new.

— What challenges are volunteer organizations currently facing?

— The primary challenge for a charitable foundation is the lack of support and interest from both the government and local authorities.

We’ve approached the regional state administration multiple times, requesting assistance in the form of funds, fuel, and raw materials for producing military supplies, but we always received the same answer — refusal.

There were no responses to letters sent to the governor. We made numerous appeals to the administration, asking for premises on preferential terms since we’re a charity foundation. Many people made promises but never followed through, constantly postponing the matter. We were knocking on a closed door, wasting our time.

From the administration, we haven’t received any tangible support. The only thing we’ve received during this time was a certificate of appreciation for supporting the Ukrainian Armed Forces. At least they acknowledged our existence — hopefully, that changes the narrative somewhat.

Within local self-government, there were individuals who tried to help us but couldn’t succeed because of the system itself. I’m grateful to them for their efforts and attempts to provide support.

We also lack volunteers who are willing to work consistently and regularly on an unpaid, enthusiastic basis.

There is, of course, a shortage of funds and donations for development. We decided to be as transparent as possible about our activities so that people understand what we do.

One of the ways we’ve shared our work is through our website, which has been active since July. During our conversation with Anatolii, it turned out that their hosting was about to expire, so Cityhost included "Military Brotherhood" in our program supporting low-budget and charitable organizations. We extended their hosting for free. You can read more about this program via the link.

— Can you tell us more about the mine protection systems you’ve developed for humanitarian demining?

— In 2023, together with my partners Yevhen Momotenko and Dmytro Miroshnychenko, we brought to life the Anti Mine Boots system — a professional piece of equipment designed for sappers, protecting them from anti-personnel mines.

We meticulously thought through every detail, collaborating with explosive ordnance disposal (EOD) experts from the 15th Separate Assault Brigade in Zaporizhzhia and consulting with military sappers from various units. Later, additional developers joined us, forming a strong team that helped us experiment with new materials, implement innovations, and refine and improve our existing models.

We conducted over 30 tests, iteratively enhancing every detail, ultimately achieving high standards in perfecting anti-mine footwear. The result is lightweight, reliable gear capable of withstanding explosives equivalent to 50–200 grams of TNT.

Our goal was to develop the ideal sapper boots that would mitigate the effects of explosions and reduce the risk of injuries to our military personnel. To achieve this, we created several different designs, performing extensive prototyping and testing to identify the best-performing models.

Our goal was to develop the ideal sapper boots that would mitigate the effects of explosions and reduce the risk of injuries to our military personnel. To achieve this, we created several different designs, performing extensive prototyping and testing to identify the best-performing models.

The design of the boots is based on Canadian technology, with the following improvements in our "EM Secure System" models:

- Enhanced material quality: Increasing resistance to rupture during an explosion.

- Reduced injury levels: Adding protective skirts to the body and soles of the boots.

- Innovative protective skirts - this is a new development that can contain nearly 98% of debris and prevent damage to the shins, especially the inner thighs, while also reducing the level of injury from explosive shock waves.

The "EM Secure Systems" boots incorporate a fundamental safety concept: absorbing the majority of the initial energy from shockwaves, fragments, and debris. The multi-level protective skirts provide two stages of defense, reducing excess pressure from the blast. This has been confirmed through numerous tests.

We conducted extensive testing with various types of mines and explosive devices. Some of these tests can be viewed on our website: https://em-secure.pro/.

Currently, we’ve obtained all necessary licenses to supply this footwear for humanitarian demining purposes. In July, we delivered the first seven pairs to our sapper-developers working on demining operations in Sumy, Kharkiv, and Zaporizhzhya. This is just the beginning.

Knowing the amount of effort, research, testing, and development that went into this project, I believe these boots will save countless lives.

— What inspires you to undertake such a monumental effort?

— There are many things that inspire us in our work. The videos sent to us reaffirm that we’re on the right path.

We try to share some of these photos and video reports on our platforms — on Facebook, Instagram, and, for sensitive content, in our Telegram channel.

One great example of how quickly our work delivers results involves a batch of anti-personnel mines. Within 28 hours of printing and assembling the mines in our workshop, the sappers deployed a trap in the Zaporizhzhia direction. Not long after, reconnaissance shared a video of a pickup truck driving off-road and detonating on one of our mines — designed, printed, and assembled by our team. I’m proud of that!

Currently, the "Military Brotherhood" Foundation is conducting two fundraising campaigns, and we kindly ask for your support:

For drones:

Card: 5375 4112 2199 5660

IBAN: UA923220010000026200347744396

https://send.monobank.ua/jar/84EgcMu4EJ

For "Incendiary Sweets" (munitions for UAVs):

Card: 5375 4112 2299 3110

IBAN: UA983220010000026209349160861

https://send.monobank.ua/jar/9b7ks3LZ5Y

Glory to Ukraine! Glory to our warriors!